Hydrogen (H2)

Wood is the industry leader in conducting hydrogen compressor performance, pulsation and mechanical vibration studies, with more than 250 hydrogen projects completed over the past 30 years.

|

Are you ready for the hydrogen economy? We are.

Wood’s vibration, dynamics and noise specialists have been supporting hydrogen projects for more than 35 years.

Our experience in the hydrogen economy ranges from large hydrogen plants with machinery of 5,000+ HP to small equipment fueling the latest hydrogen passenger vehicles to specialized compressor package design for carbon capture, utilization, and storage (CCUS) projects.

Checking all the boxes…

Our expertise includes specialized engineering services to support your project from design to startup and commissioning through to ongoing condition monitoring, field engineering and troubleshooting.

Capabilities include:

- Project specification development

- API 618 pulsation and mechanical studies

- Foundation and compressor package dynamic simulations

- Piping design studies using the Energy Institute methodology including the complimentary web-based screening tool Veridian

- Pipe stress analysis and pressure vessel design

- Torsional and lateral driveline studies

- Condition monitoring

- Multichannel field diagnostic and troubleshooting capabilities

- Vibration control products like DamperX pipe clamps and shoes

… and busting myths along the way...

MYTH: I can use the same bottle-size approach that I have used for natural gas.

Compressor package designers familiar with non-hydrogen applications are often led astray using their existing bottle sizing tools. Conventional bottle sizing tools result in bottle sizes that may be 4x larger than required.

With our experience and proprietary pulsation analysis software, we can calculate the optimal bottle sizes to meet the project’s technical requirements and help reduce CAPEX costs.

|

MYTH: Only a select few OEMs manufacture compressors for hydrogen service

It’s true that low-speed machines have been historically used in refineries for hydrogen, but so have high-speed machines. And like for any application, using the right design process is critical for smooth operations.

TRUE: Hydrogen is dangerous.

Yes, hydrogen is a dangerous gas; however, safe operation can be achieved with proper engineering and design controls. But, with the right knowledge and experience, designing for hydrogen is no different than any other gas.

MYTH: I don’t need to consider dynamic surge on centrifugal compressors when compressing hydrogen

Dynamic surge issues are not typically considered to be a problem due to the low specific gravity of hydrogen, but low-mass impellers in high flow situations can still lead to concerns.

...to a shared goal of cleaner energy!

No matter where you are on the hydrogen spectrum (green, blue, gray, brown/black, turquoise, purple, pink, red or white), if you need specialist support, we’re to help you through this transition.

Hydrogen vs natural gas

Hydrogen machinery can be treated similarly to large reciprocating compressors used in the oil and gas sector, but there are key differences to note.

Performance and troubleshooting

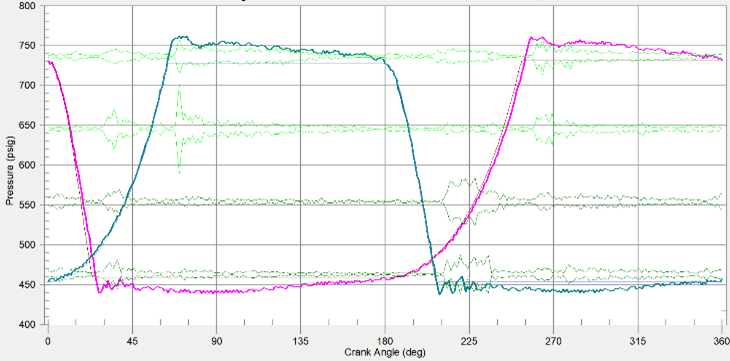

To evaluate the efficiency and health of a compressor, we can evaluate pressure-volume and pressure-crank-angle curves based on in-cylinder pressure measurements and geometries. These measurements are used to derive cylinder thermodynamic efficiencies and the overall efficiency of the compressor. After this step, Wood can evaluate losses and derive comparisons against theoretical performance behaviour.

|

|

Compressor performance curve |

Another large component of the study is inspection for abnormalities and troubleshooting. During troubleshooting activities, we collect vibration, ultrasonic, and temperature of valves with phasing to crank angle.

Additional measurements can include crosshead guide, frame, and bearing measurements if required. Utilizing correspondence to crank angle we can evaluate if events such as impact occur at the predicted times. We can also check for rod reversal and overlay vibration patterns for related knock phenomena with the help of weights and geometries.

The result provides a summary of machine health and anomalies, as well as recommendations to resolve potential issues or losses in performance.

Pulsation and mechanical studies

Key aspects of the vibration solution are determined early in the project design process. Core to many refinery processes is breaking large hydrocarbon molecules into smaller molecules and adding hydrogen at the breaks. The reciprocating hydrogen compressors scale with the process throughput and are typically very large machines, from 1,000 to 25,000 hp (750 KW to 1.9 MW).

Due to the large size and criticality, these compressors require an acoustic pulsation analysis as defined in API 618. Wood’s vibration group (formerly BETA Machinery Analysis) has been an industry leader in this area for decades.

Through our pulsation and mechanical assessments of hundreds of hydrogen compressors, we have proven that costly changes can be avoided when Wood’s vibration specialists are involved in preliminary design discussions.

Small-bore piping studies

Normal compressor frame motion can cause high amplitude, high-frequency vibrations on small nozzles and small-bore connections. Fatigue cracks often result in the shell near the small nozzle. To minimize the potential for failure, all small nozzles not absolutely required must be eliminated. If the nozzles cannot be eliminated, small-bore connections should be limited where possible.

Additionally, the cantilevered length should be as short as possible, and no unnecessary valves should be used. Keep connections plugged until needed and monitor all small-bore appendages during start-up for high vibrations.

|

|

Anti-vibration clamps |

Wood’s vibration screening tool Veridian can evaluate piping vibration risks for small and large facilities and has been used to identify high-risk locations in hydrogen piping systems that, if left unchecked, could lead to catastrophic failures.

Anti-vibration supports

All reciprocating compressor systems are at risk of failure if the system is not properly supported. Wood has engineered and fabricated a line of anti-vibration solutions field-tested and proven to reduce the vibratory response of the piping system.

Our anti-vibration clamps and braces provide robust support for many demanding applications. Solutions include anti-vibration clamps for both insulated and non-insulated services, our DamperX™ suite of fins for small-bore attachments, vibration absorbers, damping braces, and anti-vibration clamps.

Pulsation & Mechanical Analysis: Reciprocating Compressor

Pulsation study, mechanical review and frequency avoidance analysis, forced response analysis (when required); per API 618, API 688 and GMRC High-Speed Compressor Guideline.

View MorePipe Clamps, incl. DamperX™ and ThermaGlide™

Field-proven designs to control vibration and allow thermal growth in piping systems

View MoreTroubleshooting, Root Cause Analysis (RCA)

Advanced vibration analysis including pulsation, resonance, stress and transients

View More

.jpg)