Screw Compressors

Screw compressors and Roots blowers create high-frequency pulsations in discharge piping. An advanced vibration and noise analysis is often required for larger or more critical systems.

Design Requirements

Dry screw compressors generally require specially designed silencers on the suction and discharge systems to attenuate pulsations, and wet screw compressors employ oil separators which can be acoustically or mechanically resonant. To address these problems, experienced owners call Wood to evaluate the pulsations, resonances, and other aspects of the compressor package.

Pulsation and Mechanical Analysis for Screw Compressors

Vibration Inspection & Troubleshooting

To meet the vibration acceptance requirements, a vibration inspection is recommended on the main piping and small-bore connections. For noise and vibration problems, Wood provides troubleshooting support to identify frequency, resonance, or other issues, and help you implement improvements.

Troubleshooting, root cause analysis (RCA)

Pulsation & Mechanical Analysis: Screw Compressor

Including rotary compressors and Roots blowers

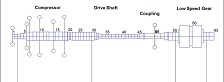

View MoreTorsional Vibration Analysis (TVA)

_-_grid.jpg)

A torsional study evaluates crankshaft, coupling, and gears to ensure torsional vibration is acceptable.

View MoreCondition Monitoring and Remote Vibration Analysis

for troubleshooting support or condition-based maintenance (CBM) applications

View More

_Vibration_Analysis_-_grid.jpg)