Knowledge Center

- Downloads

- Technical Newsletter

- Recommended Guidelines and References

- Specifications

- Technical Papers

- Tools and Calculators

- Training

- Articles, Tips and Requirements

- An Integrated Approach to Manage Vibration Risks

- Design Requirements for Reciprocating Compressors

- Evaluating Compressor Operating Risks

- Five simple methods to check reciprocating compressor performance

- Important Differences in Pulsation Software

- Liquid Pumping Systems (Including Liquid Pipelines)

- Noise Regulations Around the World

- Noise Risks in the Gas Industry

- Performance Monitoring Examples

- Pipe Support Stiffness, GMRC Project

- Piping Vibration Design Considerations

- Piping Vibration Examples

- Structural Vibration and Ways to Avoid It

- Tips for a Successful Project (Vibration Control)

- Transient Conditions on Small-Bore Piping

- Vendor Requirements for Piping Vibration & Integrity Assessment

- Vibration-induced fatigue (whitepaper)

- Vibration Issues Affecting Gas Compressor Facilities

- Ask the expert

Avoiding vibration-induced fatigue failure

How web tools enable effective piping vibration management

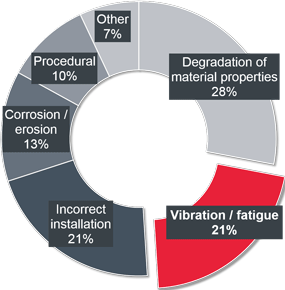

In the field of asset integrity management, it is corrosion and erosion that attracts the lion’s share of management time, resources and analysis. The majority of plants usually have a full-time corrosion or integrity engineer whose principal responsibility is identifying, preventing or mitigating possible corrosion or erosion damage events. This is because corrosion or erosion is almost inevitable, with potentially catastrophic consequences.

|

|

| Causes of hydrocarbon releases (UK Health & Safety Executive) |

In contrast, vibration and its consequences attract significantly less attention and management activity. But inadequately managing the threat of vibration can be equally catastrophic – and, in fact, accounts for a relatively high percentage of reported failures, notably in harsh environments.

However, the approach to vibration management is changing, becoming more proactive, more preventative and more global. This has been driven by three factors:

- Demand from operators with an international perspective

- Wider dissemination of existing standards and industry guidance

- Supply of enabling technologies that bring vibration to the heart of asset integrity management

Contents [ hide ]

- 1 Vibration and risk

- The Energy Institute and de facto standards

- Identifying vibration risk at the design stage

- Identifying vibration risk on operational plant

- 2 The benefits of vibration screening

- Vibration screening in real-world environments

- Enabling technology from Wood

- 3 About the author

- 4 Related information

- 5 Related services

1 Vibration and risk

|

|

| A vibration-induced failure caused a gas release and explosion at this compressor station |

Piping vibration management has traditionally been seen as a bridge to be crossed when necessary, not a problem to be addressed through pre-emptive measures. The view of vibration as a high-impact but low-probability issue about which little can be done proactively can also account for its historical absence from international piping design codes.

But this approach has, itself, created something of a vicious circle. By opting for cure over prevention, operators often miss an opportunity to gain greater understanding of the effects of vibration, the likely weak spots in their infrastructure and optimal mitigation strategies. It is telling that vibration is still considered to be something covered by rotating-machinery specialists, whereas the more insidious form of vibration affects static plant – for example, piping, vessels, valves and heat exchangers. In other words it affects offshore, subsea and topsides piping and associated static equipment; and in a largely invisible and stealthy fashion.

That said, there have been regional differences in attitudes towards vibration management. In the UK, the Energy Institute’s 2008 document [1] (the most recent output from a project looking at the threat of piping vibration first started by the Marine Technology Directorate in the mid-1990s) is the standard reference for vibration screening methodologies and management approaches. This series of joint industry projects was originally established to look at the issue of vibration and how design guidance could be developed to avoid problems that were being seen on newly commissioned installations both on and offshore.

[1] “Guidelines for the Avoidance of Vibration Induced Fatigue Failure in Process Pipework” (AVIFF); 2nd Edition; Energy Institute 2008. ISBN 978 0 85293 463 0.

The Energy Institute and de facto standards

As a methodology produced by a UK body, it is inevitable that its main focus is the UK’s North Sea continental shelf, where vibration had caused a number of high-profile issues in the 1990s for a number of operators during plant start-up and commissioning. However, it also reflects a consensus in Europe that vibration was becoming more of an issue. A report from the UK’s Health and Safety Executive also made it clear that vibration was an important issue to be considered alongside corrosion and erosion.

As a methodology produced by a UK body, it is inevitable that its main focus is the UK’s North Sea continental shelf, where vibration had caused a number of high-profile issues in the 1990s for a number of operators during plant start-up and commissioning. However, it also reflects a consensus in Europe that vibration was becoming more of an issue. A report from the UK’s Health and Safety Executive also made it clear that vibration was an important issue to be considered alongside corrosion and erosion.

There has been a notable shift to a more global approach, where the assessment of piping vibration risk through the deployment of screening methods is deemed necessary irrespective of the asset’s location. In part this has been driven by oil majors (or those with UK affiliates) who are active in the North Sea. Having used the Energy Institute’s approach toward vibration screening in their European operations for some time, they are now starting to push their operating companies in other parts of the world to consider vibration as a real issue that should, and could, be proactively addressed.

|

|

| Fatigue failures can be caused by a number of excitation sources. The majority of failures occurs at small-bore piping connections. |

Where companies don’t have that European connection, it is only in the past two or three years that interest in vibration issues has been building. Having experienced their own vibration-induced failures, companies in North America, Australia and the Middle East recognise that vibration can be a painful and expensive issue, and it is now very firmly on their radar.

Nonetheless, the Energy Institute document remains the de facto “standard” and is due a revision cycle in 2018. As mentioned above, common piping design codes have historically not addressed vibration issues in any depth, and other standards (for example API618/674/688) are limited to covering very specific aspects of piping vibration associated with positive displacement pumps and compressors. For operational plant too, the Energy Institute document currently provides the most in-depth approach to helping identify and mitigate piping vibration issues from a variety of flow-induced excitation mechanisms, and the importance of the topic for existing facilities will also be addressed by an update to API579, work on which is currently ongoing.

Identifying vibration risk at the design stage

The Energy Institute’s pre-eminent position in this particular field also accounts for another change we are seeing take hold in the oil and gas industry: vibration management during the design stage. This is further aided by some design codes (for example, ASME B31.3 (Appendix F) now referencing the Energy Institute Guidelines for direction on design for severe cyclic service.

The screening approach takes information regarding basic piping information, and the range of process conditions that the plant will be operating under, and enables operators to identify potential vibration hotspots. It is designed to give designers and operators the necessary additional information to design out potential vibration issues before the plant is built and commissioned.

|

| A proactive screening process can prevent most vibration-induced fatigue failures |

Identifying vibration risk on operational plant

|

| Visual inspection of piping and attachments |

Using piping vibration measurements to identify potential issues is a useful part of the overall toolbox of techniques available to a plant operator. However, piping vibration is often very dependent on how the plant is being operated and the flowrates that are being experienced – a vibration measurement survey is therefore often just a snapshot of what is happening at the time of the survey. However, by combining a plant-wide screening assessment with a targeted vibration measurement survey (similar to the type of screening performed on a new design) – which covers all operating scenarios – a far better understanding can be built up of the risks and process conditions under which issues might be experienced. This results in a targeted approach to vibration measurement surveys, system modifications and the implementation of suitable vibration control measures.

Risk-based vibration screening assessments use very similar, if not identical, data to that used for risk-based inspection (RBI) programmes. Screening of operational plant is being picked up by a number of the oil and gas majors who are applying the Energy Institute methods to understand their risk profile.

2 The benefits of vibration screening

However, as asset integrity management becomes increasingly important for operational, financial and HSE reasons, vibration screening is expected to become far more widely adopted. Not least, because the benefits are relatively easy to quantify.

|

| A fatigue crack on this piping connection resulted in significant downtime costs |

Where there is no vibration screening or measurement in place, should a plant experience a failure then the operator often has little option but to do a like-for-like replacement of the damaged equipment. This means that any inherent design flaw or structural weakness will also be built in – potentially leading to the same problem reoccurring. This can lead to plant shutdown or reduction in throughput while the operator hires an external consultant to analyse the failure, and then assess what needs to be done to create a more robust system. However, with screening in place, operators have far greater insight into the asset and what to do to pre-empt potential issues that might lead to a failure and unexpected downtime, especially when changes to plant operating conditions are being contemplated.

There is a bigger issue here too. A failure in one part of part of the plant might well indicate similar potential issues elsewhere. By using screening techniques that give a helicopter view of the whole process plant, operators can see where else they might be at risk – and then deploy resources accordingly, focusing on areas of potential weakness, rather than just waiting for the next failure to happen.

Vibration screening in real-world environments

The methodology and the necessary algorithms for effective vibration screening are readily available. There is growing recognition that it forms a necessary part of any effective asset integrity management programme. There is also increasing interest in applying these methodologies at design stage and on operational facilities from companies worldwide.

But practical challenges remain. As with all systems that need to be used in multi-site organisations, consistent and accurate results depend on solutions that enable multiple users to apply the most up-to-date version of the screening methodology and its data in an identical fashion each and every time. Users therefore need solutions that can ensure that each data update is immediately disseminated across the organisation and is readily available on-site to the individuals who require it.

To date, one of the biggest challenges from the technology perspective has been that the algorithms have been dropped into a spreadsheet and accessed from there. This has opened up operators to any number of ‘spreadsheet risks.’

|

| High-risk piping anomalies should be tracked from discovery to close out |

These range from simple user error that compromises the accuracy of data entry (which is inevitably exacerbated when using smaller-form mobile devices typically seen on-site); to over-reliance on the individual who developed the spreadsheet in the first place and has buried it on his or her laptop; and the possibility of flawed macros being disseminated across the organisation with a potential lack of quality checking and revision control.

The second challenge is that there has been no way of tracking issues and risks as they are identified over time. Vibration screening may take place on static plant, but it is not a static process. A time-stamped report that gathers dust on a shelf is of very limited value, however accurate its recording is. Since the consequences of vibration vary enormously as process conditions inevitably change, a snapshot view becomes rapidly out of date.

For example, having identified a number of small-bore connections on piping systems whose weakness presents a potential threat, operators really need a register of those locations so that they can be tracked over time. That register or anomaly database needs to capture the results of a line walk-down, including, for example, any poor fabrication characteristics picked up from visual inspections but absent from drawings, and any remedial action already taken. If the bracing on a particular part of piping has been updated, it changes the operating parameters in the screening methodology, and consequently the risk potential.

Building a dynamic register or anomaly database – which is linked to the screening ‘engine’ – enables operators to maintain timely information on the status of any anomalies within a highly dynamic operational environment.

Enabling technology from Wood

|

| Veridian helps operators and EPCs identify high-risk locations, track anomalies, determine remedial actions and accelerate detailed analysis of various operating scenarios |

Veridian VS is Wood’s specialist vibration screening tool. Accessible through an online browser, it enables operators to implement their own screening assessments from any location in the world. It is principally built around the Energy Institute’s methodologies. Operators input their own process data and piping information and Veridian assesses all the various vibration mechanisms that might apply and creates a likelihood of failure score for each piping run in the process system.

Veridian enables operators to adjust process parameters, so that operators can assess the risks of different production rates and feed these into broader asset integrity and operational decision-making.

Veridian can be used at the design stage as well as on existing onshore, topside and subsea applications.

Veridian AM is the enhanced anomaly management register from Wood that links to Veridian. It provides an easy-access, online database that enables maintenance and operations teams to capture all information pertinent to the vibration threat of a particular asset, including screening, line walk-down or vibration measurements.

It acts as a single source from which operators can assess the need for and prioritise remedial actions, allocate tasks and responsibilities, maintain an up-to-date record of all actions taken for a given anomaly, and monitor all such anomalies on an asset-by-asset basis worldwide. By enabling the tracking of issues from design and commissioning to operation and maintenance, Veridian AM is an essential bridge between screening and day-to-day activity; it is currently being used on a number of operational facilities.

3 About the author

|

| Rob Swindell, CEng, FImechE |

Rob Swindell has over 30 years’ oil and gas experience, working on a wide variety of on and offshore structural integrity projects related to vibration-induced fatigue issues on piping systems.

He is co-author of the Energy Institute document ‘Guidelines for the Avoidance of Vibration Induced Fatigue Failure in Process Pipework’, and has delivered a number of technical papers and participated in many industry forums throughout his career.

In his current role at Wood, Rob manages strategic ‘through-life’ facility fatigue assessments for our customers.

4 Related information

Watch the webinar recording: Small Bore...Big Problem – piping vibration management

Download the Veridian information sheet (PDF)

Contact a Veridian expert

Veridian overview

Piping vibration integrity primer (PDF)

Our piping vibration training program

Technical papers:

AIV and FIV in Pipelines, Plants, and Facilities

International Pipeline Conference 2016, Calgary, Canada (© ASME)

Testing System Set-Up to Evaluate Acoustic Induced Vibration

ASME 2016 Pressure Vessels and Piping Conference 2016, Vancouver, Canada (© ASME)

Vibration-Induced Fatigue – A Risk-Based Approach

API Inspection Summit 2017, Galveston, TX, USA

5 Related services

Veridian VS – vibration screening

Piping Vibration and Integrity Assessment

Acoustic-Induced Vibration (AIV) Analysis

Flow-Induced Vibration (FIV) Analysis

Multiphase and Slug Flow Analysis

Related Pages

Veridian • Piping System • Piping Vibration Examples (PDF) • Piping Vibration and Integrity Assessment • Small-Bore Piping Failures on the Rise (PDF) • Examples of Piping Vibration (Video) • Piping Vibration Design Considerations •

Free webinar

Learn how to select and design vibration control solutions that work – using real-world data and case studies. Register now