Knowledge Center

- Downloads

- Technical Newsletter

- Recommended Guidelines and References

- Specifications

- Technical Papers

- Tools and Calculators

- Training

- Articles, Tips and Requirements

- An Integrated Approach to Manage Vibration Risks

- Design Requirements for Reciprocating Compressors

- Evaluating Compressor Operating Risks

- Five simple methods to check reciprocating compressor performance

- Important Differences in Pulsation Software

- Liquid Pumping Systems (Including Liquid Pipelines)

- Noise Regulations Around the World

- Noise Risks in the Gas Industry

- Performance Monitoring Examples

- Pipe Support Stiffness, GMRC Project

- Piping Vibration Design Considerations

- Piping Vibration Examples

- Structural Vibration and Ways to Avoid It

- Tips for a Successful Project (Vibration Control)

- Transient Conditions on Small-Bore Piping

- Vendor Requirements for Piping Vibration & Integrity Assessment

- Vibration-induced fatigue (whitepaper)

- Vibration Issues Affecting Gas Compressor Facilities

- Ask the expert

Vibration-induced fatigue management (Offshore Magazine)

How web tools enable effective piping vibration management

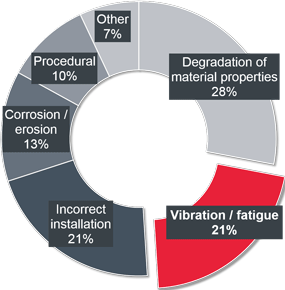

In the field of asset integrity management, it is corrosion and erosion that attracts the lion’s share of management time, resources and analysis. The majority of plants usually have a full-time corrosion or integrity engineer whose principal responsibility is identifying, preventing or mitigating possible corrosion or erosion damage events. This is because corrosion or erosion is almost inevitable, with potentially catastrophic consequences.

|

|

| Causes of hydrocarbon releases (UK Health & Safety Executive) |

In contrast, vibration and its consequences attract significantly less attention and management activity. But inadequately managing the threat of vibration can be equally catastrophic – and, in fact, accounts for a relatively high percentage of reported failures, notably in harsh environments.

However, the approach to vibration management is changing, becoming more proactive, more preventative and more global. This has been driven by three factors:

- Demand from operators with an international perspective

- Wider dissemination of existing standards and industry guidance

- Supply of enabling technologies that bring vibration to the heart of asset integrity management

Contents [ hide ]

Full article (Offshore Magazine)

Piping vibration management is not traditionally a problem that is pre-empted. However, by prioritizing cure over prevention, operators fail to spot weaknesses in their infrastructure and implement optimal mitigation strategies...

Piping vibration management is not traditionally a problem that is pre-empted. However, by prioritizing cure over prevention, operators fail to spot weaknesses in their infrastructure and implement optimal mitigation strategies...

About the author

|

| Rob Swindell, CEng, FImechE |

Rob has over 30 years’ oil and gas experience, working on a wide variety of on and offshore structural integrity projects related to vibration-induced fatigue issues on piping systems.

He is co-author of the Energy Institute document ‘Guidelines for the Avoidance of Vibration Induced Fatigue Failure in Process Pipework’, and has delivered a number of technical papers and participated in many industry forums throughout his career.

In his current role at Wood, Rob manages strategic ‘through-life’ facility fatigue assessments for our customers.

Related information

Veridian vibration screening and assessment tool

Piping vibration integrity primer (PDF)

Technical papers:

AIV and FIV in Pipelines, Plants, and Facilities

International Pipeline Conference 2016, Calgary, Canada (© ASME)

Testing System Set-Up to Evaluate Acoustic Induced Vibration

ASME 2016 Pressure Vessels and Piping Conference 2016, Vancouver, Canada (© ASME)

Vibration-Induced Fatigue – A Risk-Based Approach

API Inspection Summit 2017, Galveston, TX, USA

Related services

Piping Vibration and Integrity Assessment

Acoustic-Induced Vibration (AIV) Analysis

Flow-Induced Vibration (FIV) Analysis

Multiphase and Slug Flow Analysis

Related Pages

Veridian • Examples of Piping Vibration (Video) • Piping Vibration Examples • Piping System • Piping Vibration Design Considerations • Piping Vibration and Integrity Assessment • Small-Bore Piping Failures on the Rise (PDF) •

Free webinar

Learn how to select and design vibration control solutions that work – using real-world data and case studies. Register now