Reciprocating Compressors

VDN is the world’s largest provider of compressor pulsation and vibration services. Working with VDN results in:

- Superior reliability and smoother operations

- Reduced vibration problems and lower maintenance costs

- Responsive design and field support

Design Requirements

This comprehensive chart outlines the required scope and options per API 618 and GMRC High Speed Compressor Guideline.

The scope applies to new (or modified) compressors. For problems with existing compressors, contact our field troubleshooting group.

Design requirement for Reciprocating Compressors

What are pulsations?

Pulsation forces in the piping system can be up to 10,000 lbf (44,500 N), causing piping failures.

For an explanation of pulsation forces and other dynamic forces on a reciprocating compressor, see our training video:

Module 2: Pulsations and Other Forces in a Reciprocating CompressoR

Webinar: Vibration problem solving – back to basics

On-site troubleshooting – part 1: back to basics

View MorePulsation & Mechanical Analysis: Reciprocating Compressor

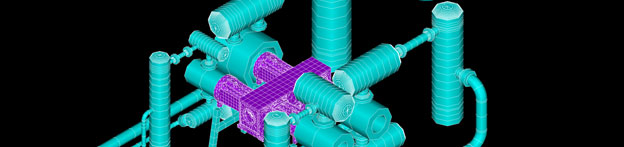

Pulsation study, mechanical review and frequency avoidance analysis, forced response analysis (when required); per API 618, API 688 and GMRC High-Speed Compressor Guideline.

View MoreFive simple methods to check reciprocating compressor performance

How to spot-check the performance of a reciprocating compressor

View MoreBottle Sizing Service

This service provides recommended sizing for pulsation bottles used on reciprocating compressors.

View MoreSpecifications

Specs and guidelines for vibration, stress, pulsation, and dynamic studies, including commissioning and reliability/integrity inspection services.

View MoreStructural Vibration and Dynamic Design Analysis

for FPSOs, Platforms, Elevated Structures

View MoreTorsional Vibration Analysis (TVA)

_-_grid.jpg)

A torsional study evaluates crankshaft, coupling, and gears to ensure torsional vibration is acceptable.

View MoreTroubleshooting, Root Cause Analysis (RCA)

Advanced vibration analysis including pulsation, resonance, stress and transients

View MoreMotion Amplification Vibration Analysis

For improved vibration analysis of piping, machinery and structures

View More

_Vibration_Analysis_-_grid.jpg)